Vital Resources

The Surprising Benefits of Hops (Humulus lupulus) for Cardiometabolic Health, Appetite Regulation, and More*

Hops (Humulus lupulis) is a humble plant that has a rich history in herbal medicine and is increasingly recognized for...

Learn More

The B-Vitamin Complex: Breaking Down Their Health Benefits

The B vitamins are the unsung heroes of your body’s metabolic processes. This family of water-soluble vitamins plays critical roles...

Learn More

Supporting Your Immune System: Choosing the Right Supplement

Our immune system is central in maintaining overall health—helping our bodies defend against harmful pathogens like viruses and bacteria. However,...

Learn More

Unveiling the Health Benefits of Licorice: From Ancient Remedy to Modern Supplements

Licorice has been a cornerstone in herbal medicine for thousands of years across the world. Its root has been used...

Learn More

Support Immune Health: Preventing Colds and Flus With Science-Backed Strategies

As the colder months roll in, many of us start to dread cold and flu season for ourselves and our...

Learn More

Nourish Your Mind With These Top 10 Foods for Brain Health

Your brain is the most complex organ in your body, controlling everything from your thoughts and emotions to your memory...

Learn More

GLP-1 and Gut Health: How the GLP-1 Hormone Aids Metabolic and Digestive Wellness

The gastrointestinal system is central to our overall health–influencing digestion, nutrient absorption, and metabolism. One of the body’s key players...

Learn More

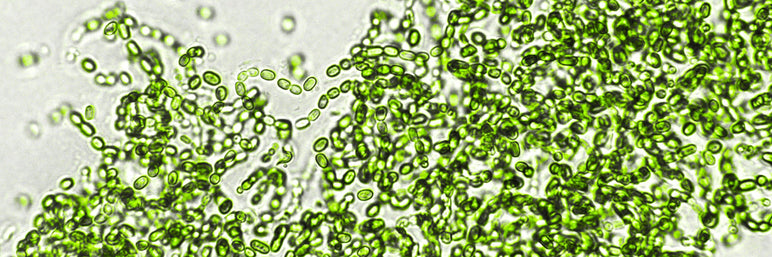

Meet Akkermansia: The Gut Microbe Supporting GLP-1 and Digestive Health*

In recent years, scientists have identified specific gut bacteria that impact digestion, immune health, and metabolic health. One such beneficial...

Learn More

Unlocking GLP-1 Receptors: The Key to Metabolic, Hormonal, and Digestive Health*

Our bodies rely on a delicate balance of hormones to regulate the numerous essential functions that take place, down to...

Learn More

Leaky Gut or IBS? Try These Pre- and Probiotics

If your healthcare practitioner has recommended you take a prebiotic and probiotic supplement to address your leaky gut syndrome, you...

Learn More

The Vital Role of Sleep: How Rest Influences Your Health

To optimize health, at least 20% of nighttime sleep should occur in deep sleep cycles, characterized by the slowest brain...

Learn More

How and When to Take Probiotics for Maximum Benefits

You may have started taking a probiotic supplement based on a practitioner’s recommendation or information you’ve read or heard. Smart...

Learn More

Setting up Your Practice’s Natural Dispensary for Optimal Patient Health

Establishing a natural dispensary within your healthcare practice is a strategic move that can significantly benefit both your patients’ health...

Learn More

Optimizing Eye Health Through an Integrative Lens

The eyes are not only a window to the world but also a reflection of our overall health, and yet...

Learn More

Digestive Enzyme Supplementation and Bloating: A Functional Medicine Approach

Have you ever experienced that uncomfortable, swollen feeling in your abdomen after a meal, leaving you wondering if there is...

Learn More